HOW ERGONOMICS TRAINING CAN BENEFIT YOUR EMPLOYEES AND INCREASE YOUR PROFITABILITY

Ergonomics training is a highly effective program for keeping your employees aligned and aware of their bodies.

Ensuring that your employees remain healthy and safe while on the job boosts morale and increases your company’s profitability. Ergonomics training involves using scientific knowledge of anatomy and engineering to reduce the amount of strain your employees experience while performing normal work tasks. An ergonomics training program is designed to lower the risk of work-related injuries and improve employee productivity and morale through well-being. Increase your profitability by maximizing your workforce’s satisfaction and productivity.

Basics of Training

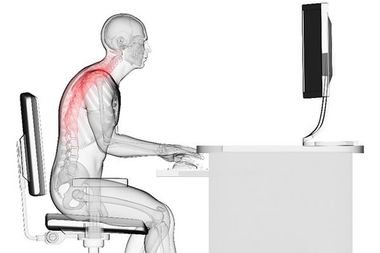

The exact training procedures for ergonomics depend on the type of work environment; your ergonomics trainer will formulate a program based on whether you operate out of traditional offices, retail businesses, construction sites or industrial warehouses. In general, ergonomic training involves teaching employees basic ergonomic principles and how to apply those principles to the workplace. Topics that are typically covered during training include safe work practices, greater awareness of tasks that raise the risk of injury, and the proper use of workplace tools, machines, and equipment. For example, in an industrial ergonomics program, employees who operate heavy machinery would learn how to stand properly while working to reduce their risk of developing lower back problems or other musculoskeletal disorders. Employees who have desk jobs would learn how to position themselves at their computer to reduce strain on their neck and upper back. After going through ergonomics training, employees should also understand how to report workplace injuries or health conditions. Understanding why it is important to recognize and report injuries as early as possible helps ensure that employees receive proper medical care to prevent their condition from becoming worse, potentially leading to work absenteeism.

Benefits of Ergonomics

Ergonomics training provides several benefits for both workers and business owners, including the following:

- Improved morale Employees experience less physical discomfort on the job, which makes them better able to perform well on a consistent basis. Ergonomics training also shows your employees that their employer is taking measures to protect their health and safety, leading to improved relations between you and your employees.

- Increased productivity Ergonomics principles make it easier for employees to do their job efficiently, which helps them become more productive. With the greater ease of movement that ergonomics allows, employees can accomplish more in a typical workday than they would when experiencing discomfort or strain while working.

- Improved attendance Ergonomics reduces the risk that your employees will develop health problems or sustain injuries that cause them to miss work. Employees will also learn to recognize problems early on, resulting in prompt treatment that can prevent injuries from becoming more serious.

Increased Profitability

Ergonomics training can boost your company’s bottom line by ensuring that your employees are working as efficiently as possible. An increase in efficiency and productivity means that work tasks and projects are completed on schedule, leading to satisfied customers and clients. Because ergonomics also decrease the risk of worker injury, you can reduce the costs involved in lost production hours and high-turnover rates. It’s almost always cheaper to keep the employees you have happy than to re-train a replacement.

Fewer injuries and work-related health conditions result in a lower number of compensation claims, which can add up to considerable savings over time. Having an ergonomics assessment can help you determine if your company is doing enough to protect your employees.

For more information about ergonomics training in Arkansas, contact SEA Inc. at 501-568-3111 to speak with one of our certified trainers.

Stepping into a new safety leadership role should be accompanied by a clear transition plan. Too often, it doesn’t. Instead, you inherit outdated procedures, expired training records, unresolved hazards, disengaged supervisors, and a workforce that has stopped taking safety seriously. In some cases, you’re walking into the aftermath of OSHA citations, injury spikes, or leadership turnover. The good news? Even a broken safety culture can be rebuilt — but it requires structure, focus, and decisive action.

Valentine’s Day is about commitment—and in manufacturing, one of the most meaningful commitments an organization can make is to support workplace safety. Safety isn’t a one-time initiative or a binder on a shelf. It’s a system that requires attention, reinforcement, and ongoing support. In fast-paced manufacturing environments, even strong safety programs can weaken over time without adequate resources.

f you think PFAS regulation is someone else’s problem, think again. The regulatory environment around per- and polyfluoroalkyl substances is shifting rapidly, and safety, environmental, and operations teams are squarely in the crosshairs. Rather than scrambling when the deadlines arrive, your best strategy is to act early.