Mastering Dust Dangers: Key Insights on Combustible Dust Safety

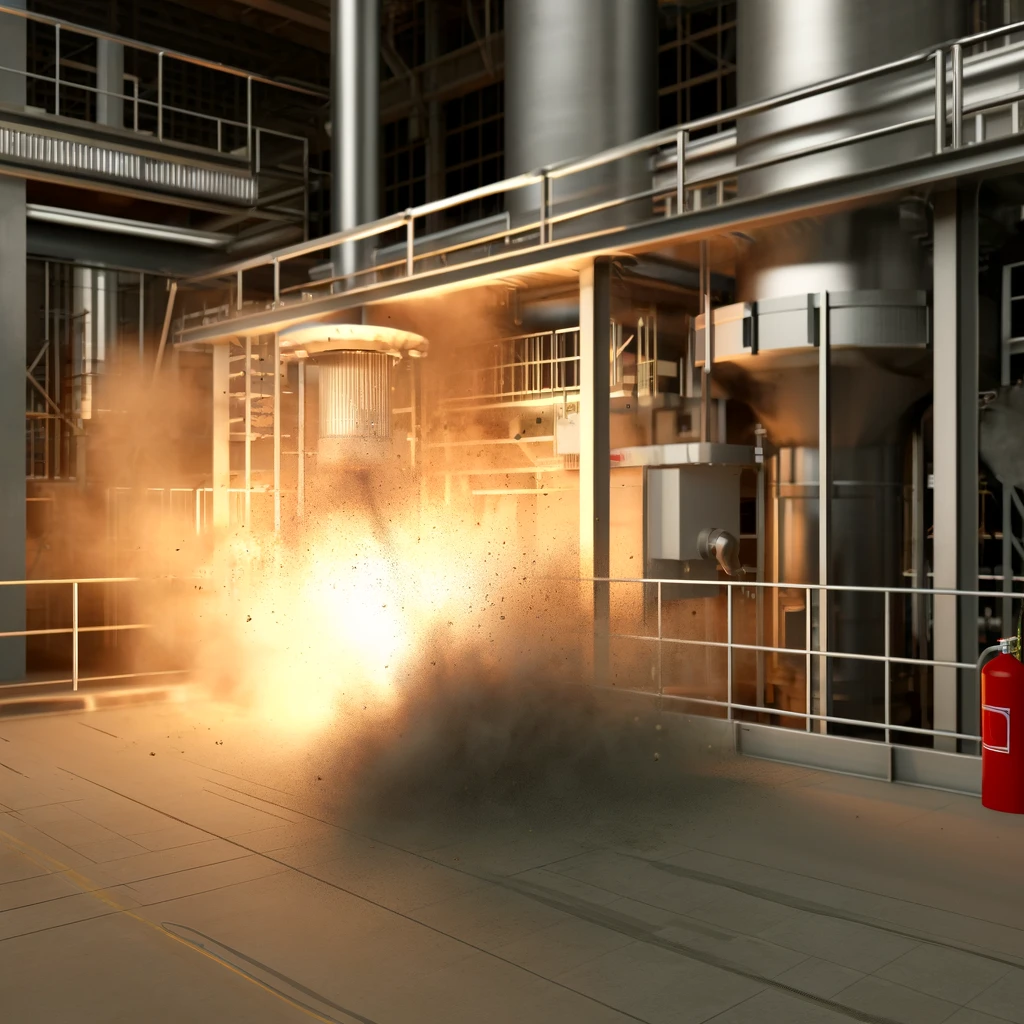

The hazards posed by combustible dust are often underestimated until it's too late. These fine particles, when suspended in the air under certain conditions, can lead to catastrophic explosions, resulting in severe injuries, fatalities, and the destruction of buildings. For example, a tragic incident occurred in a metal processing plant where a combustible dust explosion resulted in the loss of several lives and substantial property damage. This serves as a stark reminder of the potential dangers lurking in what might seem like harmless dust accumulations. While the Occupational Safety and Health Administration (OSHA) has yet to establish a specific standard for combustible dust, it recognizes the severity of these hazards through its National Emphasis Program (NEP) (CPL 03-00-008). This program aims to guide inspections targeting industries known for frequent or severe dust-related incidents, including agriculture, chemical manufacturing, and recycling operations. OSHA also provides valuable guidance materials to help businesses understand and mitigate these risks.

What Qualifies as Combustible Dust?

Combustible dust can come from a variety of sources, including both organic and metallic materials. These are finely divided particles such as:

- Metal dusts, including aluminum, magnesium, and some iron forms.

- Wood dust.

- Carbon-based dusts like coal and carbon black.

- Organic dusts from sugar, flour, paper, rubber, soap, and dried blood.

- Dusts generated from human and animal food processing.

- Textile fibers and dust.

These materials may seem innocuous in larger chunks, but as dust, they can burn rapidly and explosively under the right conditions.

The Dynamics of Dust Explosions

A combustible dust explosion is more complex than a typical fire. It requires five elements— known as the "dust explosion pentagon":

- Oxygen (from air)

- Heat (from an ignition source)

- Fuel (the combustible dust itself)

- Dispersion (a cloud of dust particles in a sufficient quantity and concentration)

- Confinement (an enclosed or semi-enclosed space)

If any element of this pentagon is missing, an explosion cannot occur. However, once ignited, the dust cloud can lead to rapid and violent combustion, often manifesting first as a primary explosion within process equipment or enclosed spaces, followed by secondary explosions as additional dust is disturbed and ignited.

Preventative Measures and Safety Programs

To effectively manage these risks, OSHA recommends conducting thorough hazard assessments that cover:

- Materials handled.

- Operations conducted, including by-products.

- All spaces, even those less obvious.

- Potential sources of ignition.

Implementing a written combustible dust safety program is a best practice for any facility handling potentially explosive dusts. This program should:

- Define specific safety procedures tailored to the organization.

- Communicate and ensure understanding of these procedures among all employees.

- Outline steps to control dust, ignition sources, and potential damage, minimizing injury and property damage risks.

How SEA Can Assist You

At Safety & Environmental Associates, Inc. (SEA), we understand the complexities of managing combustible dust risks. We offer comprehensive services tailored to your needs, including material testing, dust hazard analysis, hazard classification, and effective grounding techniques.

Don't wait for an incident to remind you of the importance of dust safety. Contact SEA today to ensure your operations are safe and compliant. Together, we can create a safer working environment that protects both your workforce and your facilities.

By Derek Jennings, President SEA